CCC Controller S3++

The Series 3++ is a drop-in replacement for Series II, Series 3, and Series 3 Plus single-loop controllers—offering modern performance with no engineering or wiring changes.

It retains the same form factor and configuration while upgrading the interface and electronics.

Supported Applications:

- Driver & Speed Control

- Extraction Control

- Antisurge & Performance Control

- Dual-Loop Control

CCC Prodigy

The Prodigy is a powerful, scalable control platform designed for the most demanding turbomachinery systems.

From compact simplex setups to large duplex I/O systems, it delivers real-time control, high efficiency, and system safety.

Key features:

- Supports standard and custom control logic (IEC 61131-3)

- Eliminates need for separate PLCs

- Ideal for compressors, turbines, and auxiliary equipment

- Flexible architecture for any system size

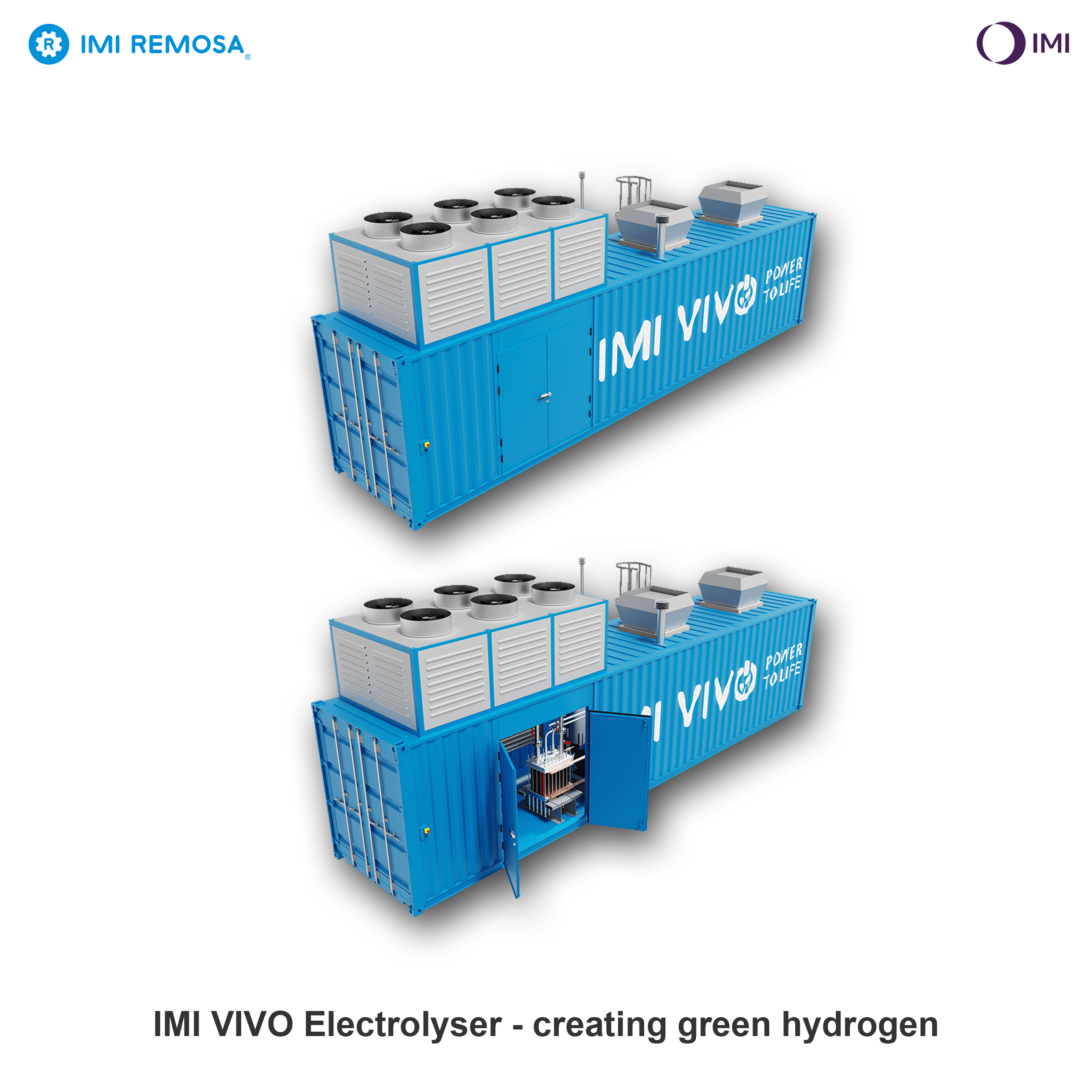

IMI VIVO Electrolyser

As part of its commitment to clean energy, IMI has entered the green hydrogen market with the IMI VIVO Electrolyser—a turnkey system that uses renewable energy (solar, wind, or geothermal) to convert water into green hydrogen.

This solution supports the global energy transition and is fully customizable to meet specific needs and regulations.

Key features:

- Complete package with integrated electrolyser and hydrogen storage

- Powered by renewable energy to produce zero-emission hydrogen

- Customizable design with optional fuel cell integration

- Built to ISO 22734 standards

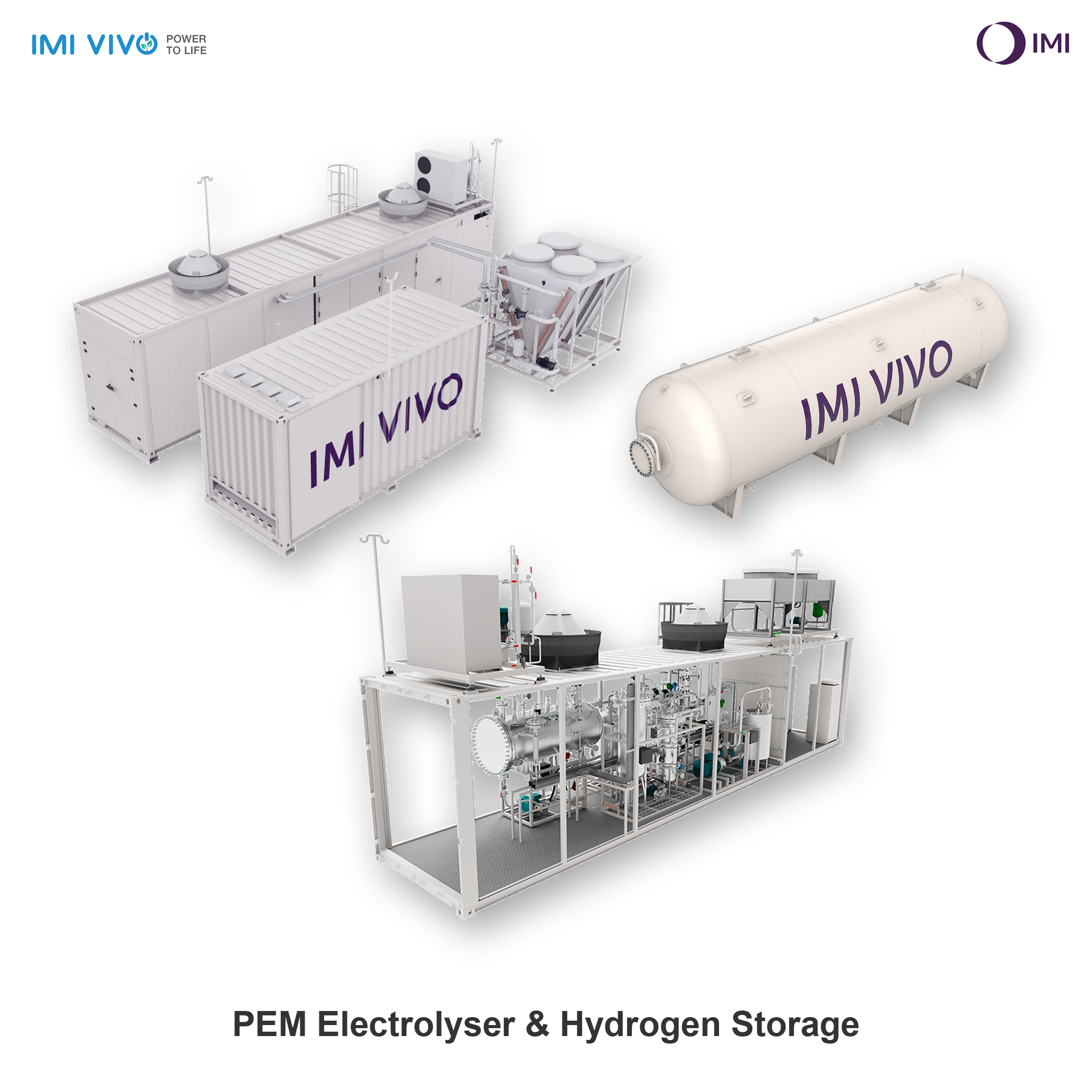

PEM Electrolyser & Hydrogen Storage

IMI VIVO’s hydrogen storage solutions allow hydrogen produced from renewable sources—like wind, solar, or geothermal—to be safely stored for later use or transport.

The stored hydrogen can be utilized on-site or delivered to other facilities for clean energy generation.

Key features:

- TYPE I metal storage vessels certified to international standards (ASME, EN)

- Standard operating pressure up to 50 barg, with higher options available

- Designed for seamless integration with electrolyser systems

IMI Diverter Valves

The IMI Remosa Diverter Valve enables smooth redirection of flow between two outlet lines,

offering several performance-enhancing features:

- Customizable Design: Tailored to specific requirements while maintaining top-tier safety and quality.

- Leak Prevention: Purging injection system helps prevent downstream leaks when switching outlets.

- Thermal Flexibility: Floating cone design compensates for temperature-induced expansion, ensuring reliable operation.

- Durable Lining: In-house refractory lining and optional anti-erosion coatings provide extended service life in harsh conditions.

IMI Slide Valves

Key Advantages of IMI Remosa Slide Valves:

- Easy Maintenance: The valves are designed so that parts exposed to wear and erosion can be easily replaced.

- Precision Assembly: CNC machining ensures accurate fitting of parts during assembly.

- Durability Under Stress: High temperatures and erosion are addressed using premium materials and specialized alloys, crafted by skilled workers to withstand extreme stress.

- Reliable Manufacturing: The production process includes continuous quality checks and uses Finite Element Analysis (FEA) to ensure structural strength under pressure and load conditions.

- Flow Optimization: Advanced computational simulations are used to analyze valve performance in complex piping systems.

IMI Double Clapet Isolation Valves

- Continuous Operation: The patented valve design allows maintenance on the Expander without shutting down the FCC unit.

- Advanced Sealing: The disc and seat feature Stellite coating for durability, accommodate thermal changes, and prevent erosion and leaks (Class V certified).

- Double Disc Safety: Dual discs with nitrogen pressurization ensure safe isolation, preventing operator exposure to hot gases.

- Efficient Flow: Engineered for smooth flow with minimal energy loss and no wear on sealing surfaces.

- Automated Control: Integrated with IMI Remosa’s hydraulic system for reliable open/close operation.

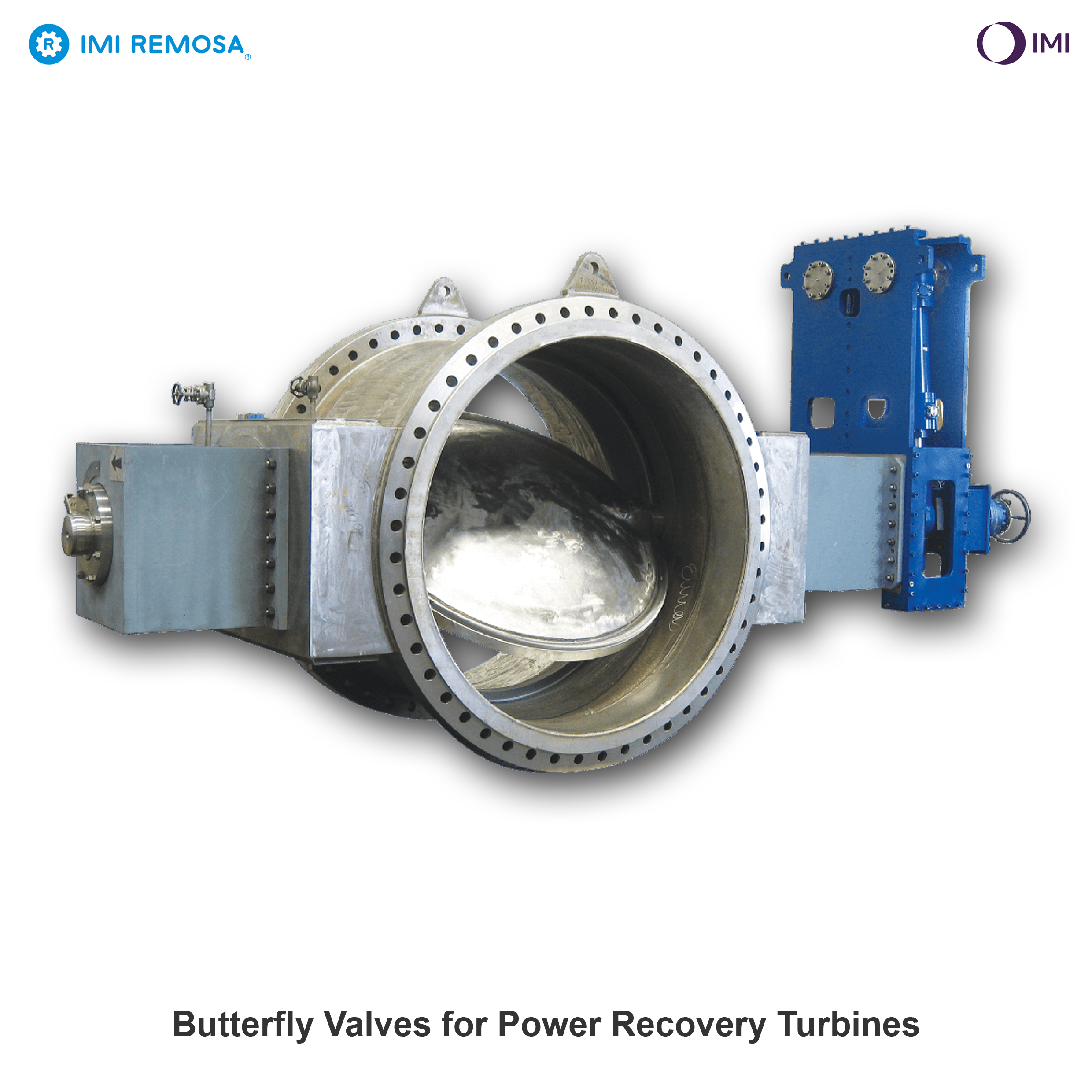

IMI Butterfly Valves

- Rapid Shut-Off: Operates in just 0.5 seconds to prevent turbine overspeed, featuring SIL3-certified emergency shutdown solenoids.

- Flexible Operation: Offers automatic throttling with options for remote control and backup systems.

- High Durability: Handles temperatures up to 950°C using a lightweight domed disc and a strong nickel alloy shaft.

- Customizable Design: Available in sizes from 8" to 150", with options for both flanged and welded connections.

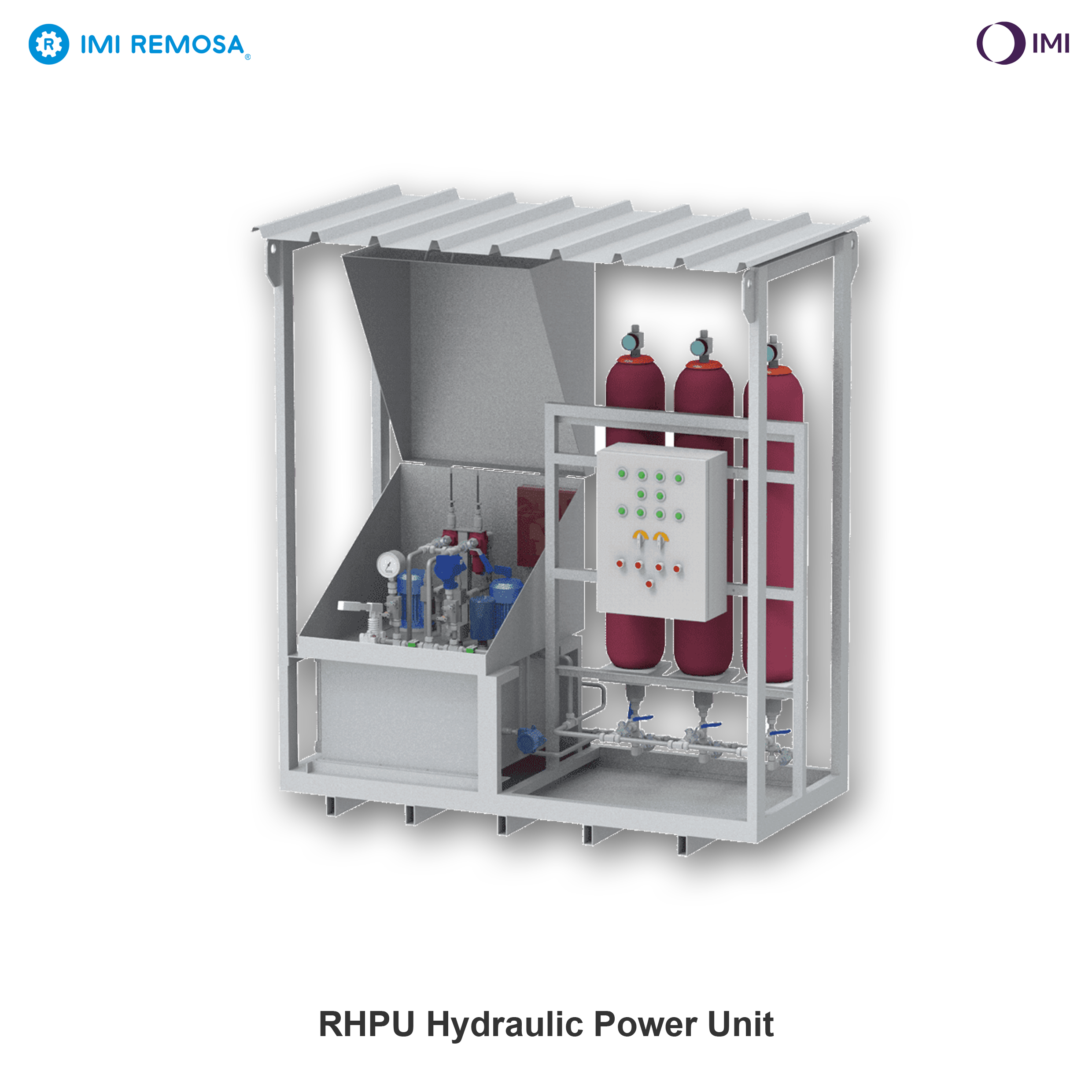

IMI RHPU

The Remosa Hydraulic Power Unit offers powerful, precise, and rapid performance in a durable and intelligent design.

It includes backup hydraulic energy storage, ensuring continuous operation even during extended power outages. Built to withstand tough conditions, it is certified for use in hazardous environments (Atex, UL, IECEX, FM, CSA) and is suitable for both onshore and offshore use.

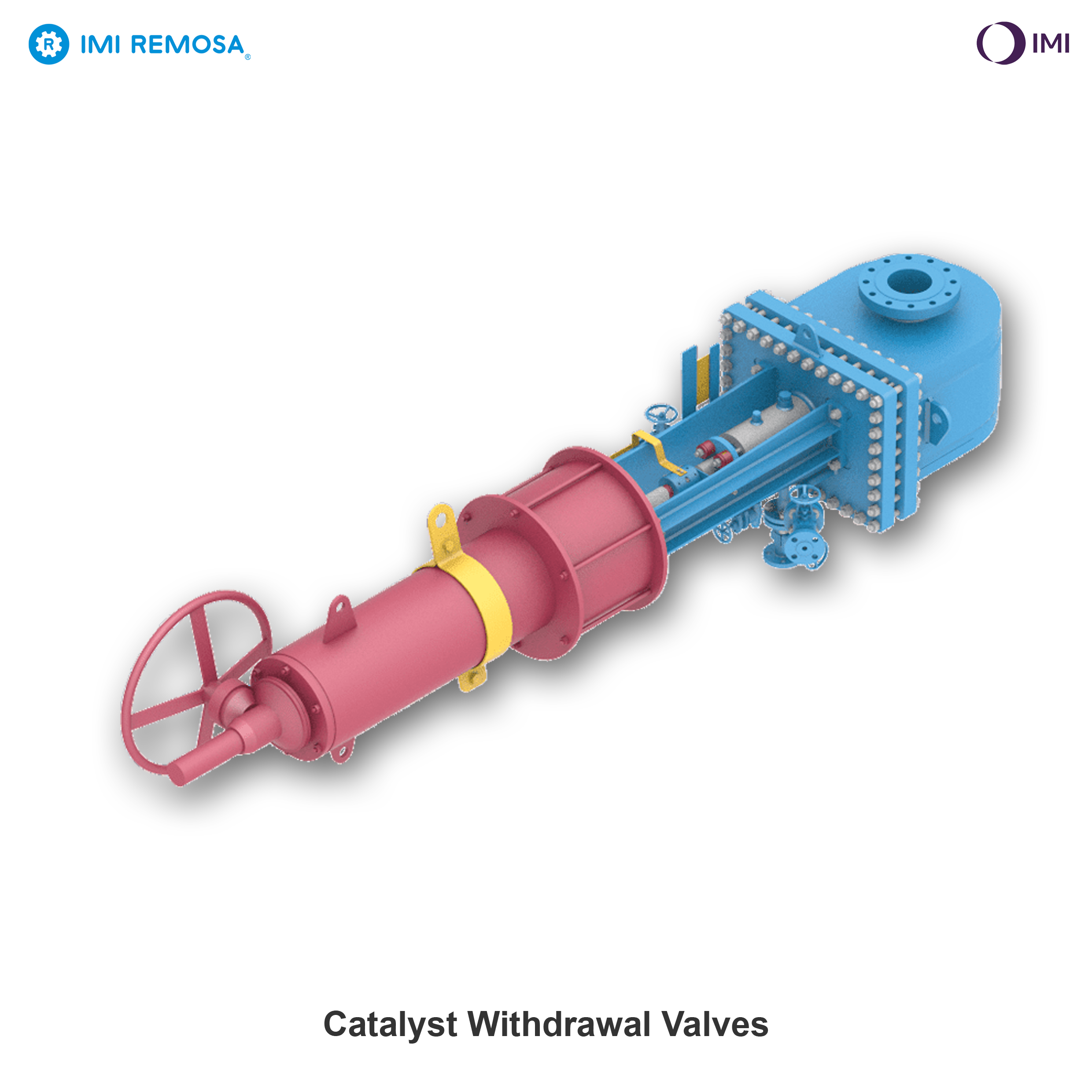

IMI Catalyst Withdrawal Valves

Engineered for extreme conditions involving high heat and erosion, these valves are ideal for catalyst withdrawal systems.

Two configurations:

- Control Valve – Features suspended, replaceable trim with an orifice plate and guides, plus anti-erosion lining.

- On/Off Valve – Utilizes a wedge-style disc with a T-head stem for tight shut-off and reduced installation footprint.

- Durable Construction: Built from forged and plate materials only (no cast parts), with critical components hard-faced in Stellite™ #6 for superior erosion resistance.

- Customizable design, Stellite™-coated sealing surfaces, and compliance with API 598 standards (on/off type).

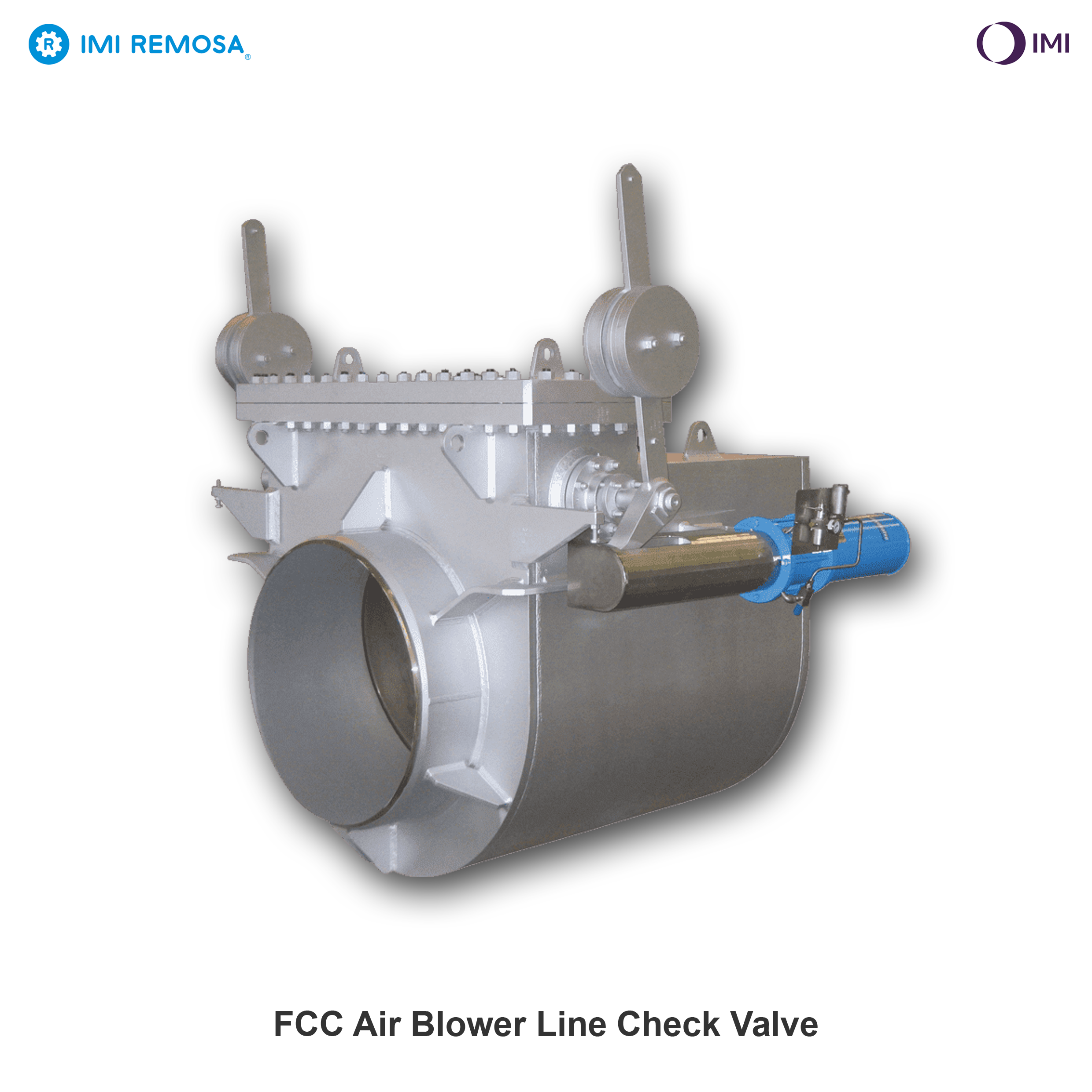

FCC Air Blower Line Check Valve

Designed to prevent catalyst backflow in FCC systems, these check valves deliver high compressor protection through a rugged and feature-rich construction.

Fully customizable to plant needs, available in SA 516 Gr70 carbon steel, 304H stainless steel, or other materials on request.

Features:

- Fabricated from forged and plate materials (no cast parts)

- Cobalt hard-facing on disc and seat for erosion resistance

- Bolted bonnet for easy internal maintenance without line removal

- Pneumatic cylinder with spring return

- Oil dashpot to minimize vibration and chatter

- etc

FCC Hollow or Cone Type Plug Valve

IMI Remosa plug valves are designed to regulate catalyst circulation in FCC units, tailored to meet the specific requirements of each process licensor.

As a critical component in the FCC reactor and regenerator loop, this valve type boasts the largest global install base—and includes the world’s largest plug valve of its kind.

Key Features:

- Precisely engineered to licensor specifications

- Critical for controlling catalyst flow in FCC systems

- Built from forged SA182 F304H stainless steel

- Cone and seat lined with abrasion-resistant material

- Minimized erosion and reduced wear from plug-to-seat contact

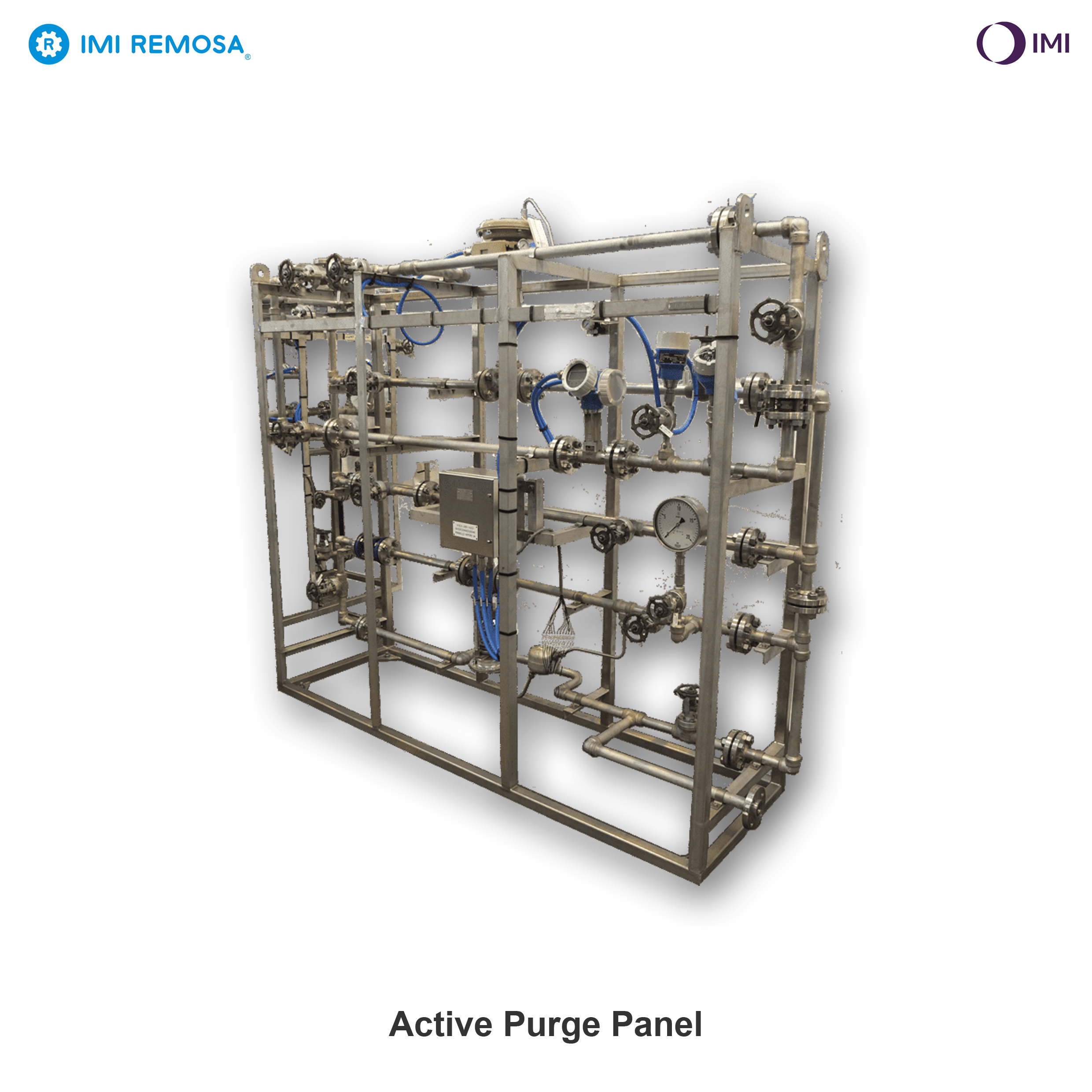

IMI Active Purge Panel

IMI Remosa’s Active Purging Panel offers automated, PLC-controlled purging for FCC valves, ensuring reliable performance under all process conditions. Real-time monitoring and adjustments protect valve components and support predictive maintenance.

Key Features:

- Fully automated PLC control

- Real-time flow, pressure, and temperature monitoring

- Supports both central and local PLCs

- Prevents valve damage during startup/shutdown

- Alarm system for flow anomalies and steam issues

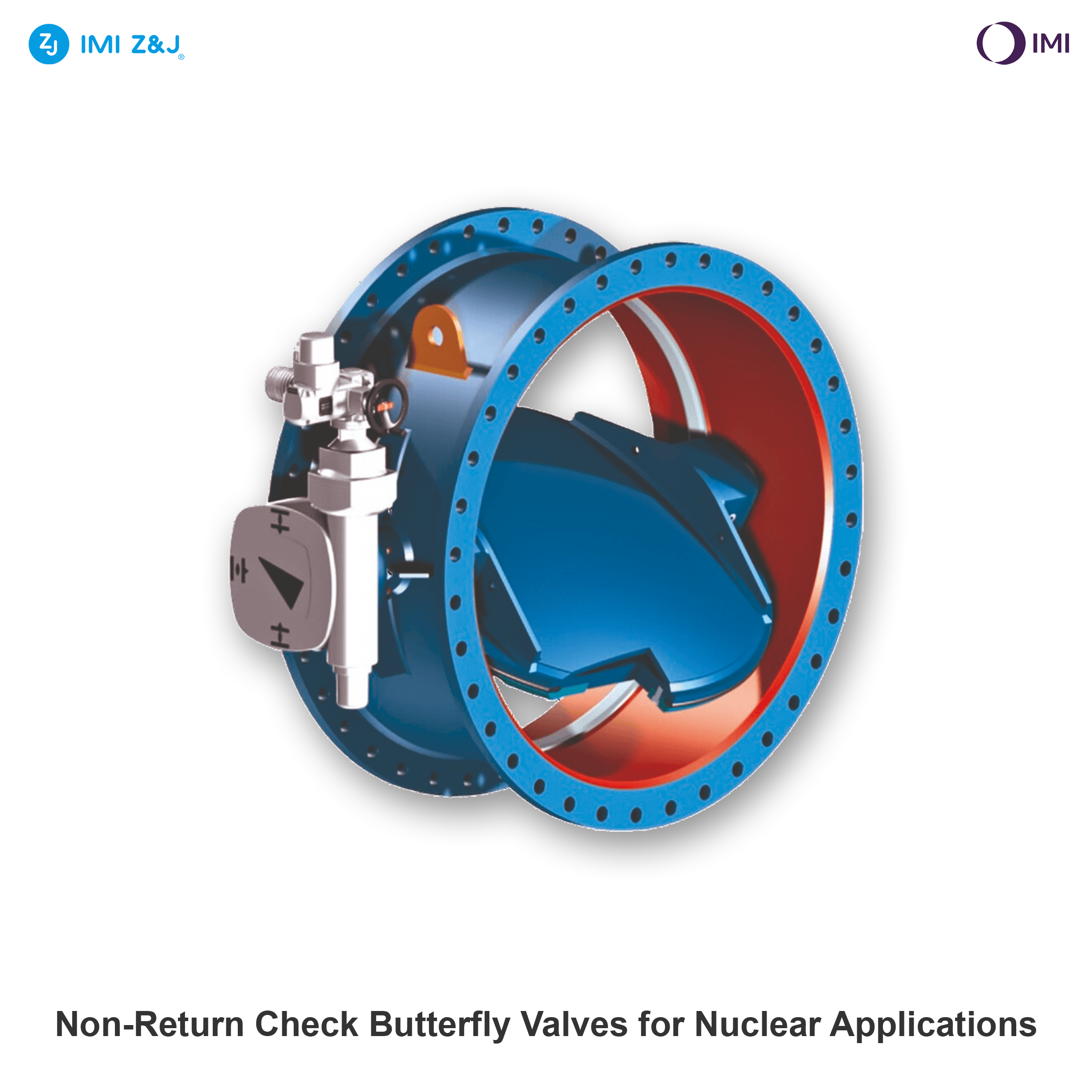

IMI Non-Return Check Butterfly Valves

Engineered for nuclear and industrial applications, these large-diameter valves (up to 4000mm) provide reliable bidirectional sealing and versatile drive options, including counterweight actuation. Built to resist corrosion and cavitation, they ensure dependable flow control in cooling circuits.

Key Features:

- Compliant with international nuclear standards

- Handles sea, river, hot/process water, and steam

- Soft sealing up to 120°C

- Materials: Carbon Steel, Stainless Steel, NAB

- Corrosion and cavitation resistant

- Available with multiple actuation methods

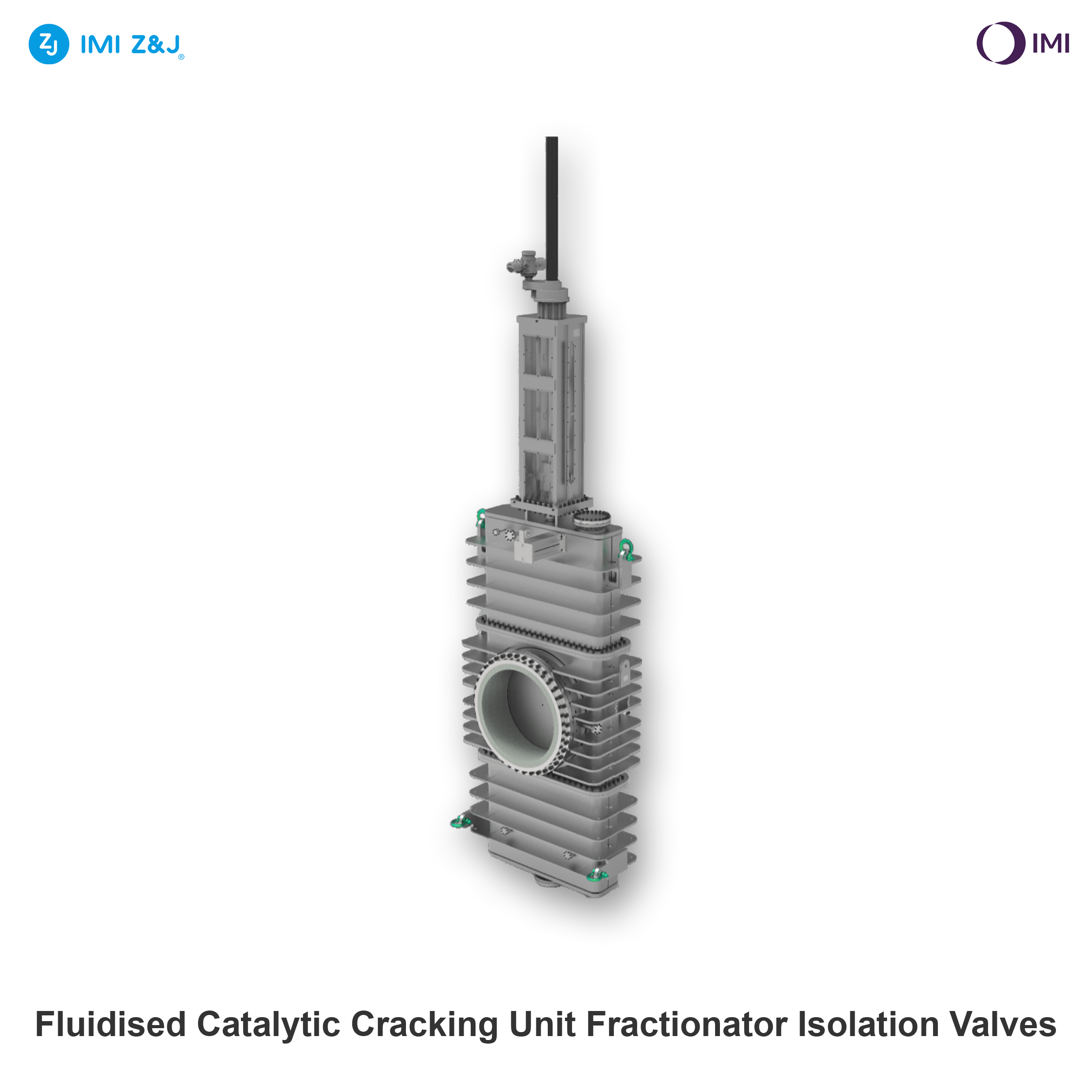

Fluidised Catalytic Cracking Unit Fractionator Isolation Valves

Designed for FCC fractionator isolation, IMI Z&J’s double disc valves ensure safe, reliable shut-off with automatic line blinding. Built to handle harsh conditions, these valves protect against erosion and media buildup while offering flexible installation and tailored materials.

Key Features:

- Double block and purge shut-off with line blinding

- Erosion-resistant seats and discs

- Clean valve cavity—resists coke and media buildup

- Horizontal, vertical, and custom mounting options

- Reinforced body for line load durability

Delayed Coking Top Unheading Valve

Built for severe refining environments, IMI Z&J’s Top Unheading Valve uses a proven double disc gate design to deliver true double block and purge. It provides tight sealing, thermal stability, and reliable performance under high pressure and frequent cycling.

Key Features:

- True double block and purge with dual discs

- Thermal distortion resistance reduces erosion and steam use

- Active mechanical seating ensures high tightness

- Hard-faced seats for corrosion and wear resistance

- No cooling water required—lowers maintenance

- Available with electric or hydraulic actuators

- Minimal spare parts needed for upkeep

Delayed Coking Bottom Unheading Valve

IMI Z&J’s Bottom Unheading Device uses trusted Double Disc Gate Valve Technology to ensure safe, automated unheading for delayed coking units. It enhances safety, reduces steam use, and simplifies operation in demanding environments.

Key Features:

- Dual discs for enhanced sealing performance

- Double block and purge design for high safety

- Lower purge steam requirement to reduce costs

- Corrosion and wear resistant for long service life

- No cooling water needed—easier maintenance

Delayed Coking Bottom Unheading with Compact Design

IMI Z&J’s fully automated Bottom Unheading Device ensures safe and efficient unheading in delayed coking units. Based on proven double disc gate valve technology, it minimizes operational risks and maintenance demands in harsh conditions.

Key Features:

- Two independent discs for superior sealing

- Double block and purge for enhanced safety

- Lower steam usage for cost efficiency

- Corrosion and wear resistant construction

- No cooling water needed for simpler operation

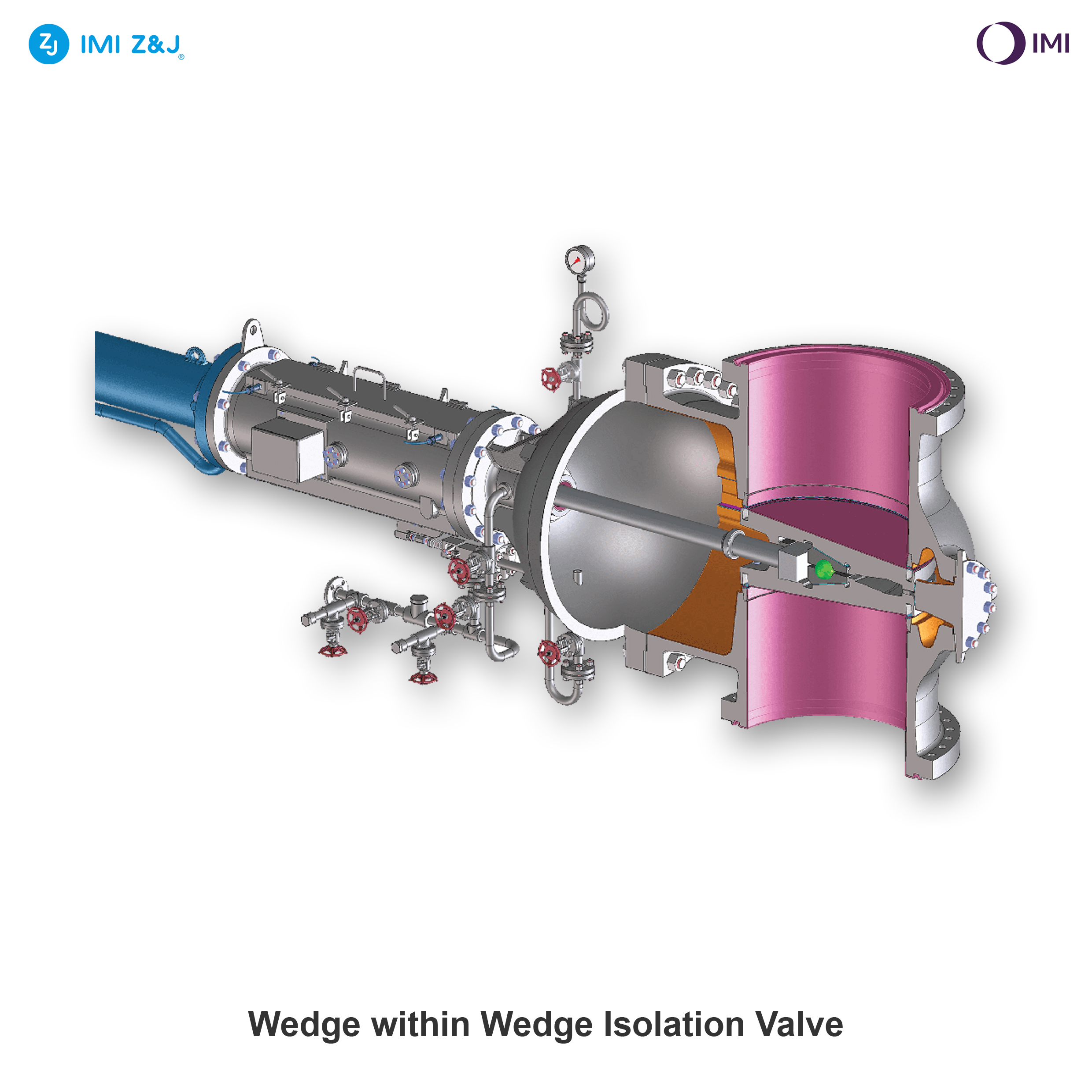

IMI Wedge Isolation Valve

With over 60 years of field-proven performance, IMI Z&J’s patented wedge-within-wedge gate valve is built for extreme conditions—handling high temperatures, pressures, and frequent cycling with outstanding reliability.

Key Features:

- Double disc design for double block and purge or bleed

- Metal-to-metal seating for corrosion and wear resistance

- Rising stem (O&Y type) for easy inspection and smooth operation

- Flanged or butt-weld end connections available

IMI Ethylene Transfer Line and Decoking Valves

IMI Z&J’s double disc valves deliver true double block and purge safety in a single body—ideal for ethylene cracking and decoking without shutdown. Proven in harsh conditions with reliable sealing and long-lasting durability.

Key Features:

- Two independent discs for enhanced safety

- Mechanical seating force for tight shut-off

- Full or reduced bore, flat or round body

- Metal-to-metal seats resist wear and corrosion

- Mountable in any orientation

- Custom-built to international standards

Fluidised Catalytic Cracking Unit Flue Gas Isolation Valves

This valve ensures complete media isolation with zero leakage for safety-critical gas systems. Built to handle high temperatures and prevent jamming, it offers dependable shut-off even under fluctuating thermal conditions.

Key Features:

- 100% tight shut-off for Man-Safe isolation

- Operates in hot-wall and cold-wall conditions

- Installs in horizontal, vertical, or inclined positions

- Designed for thermal fluctuation and zero jamming

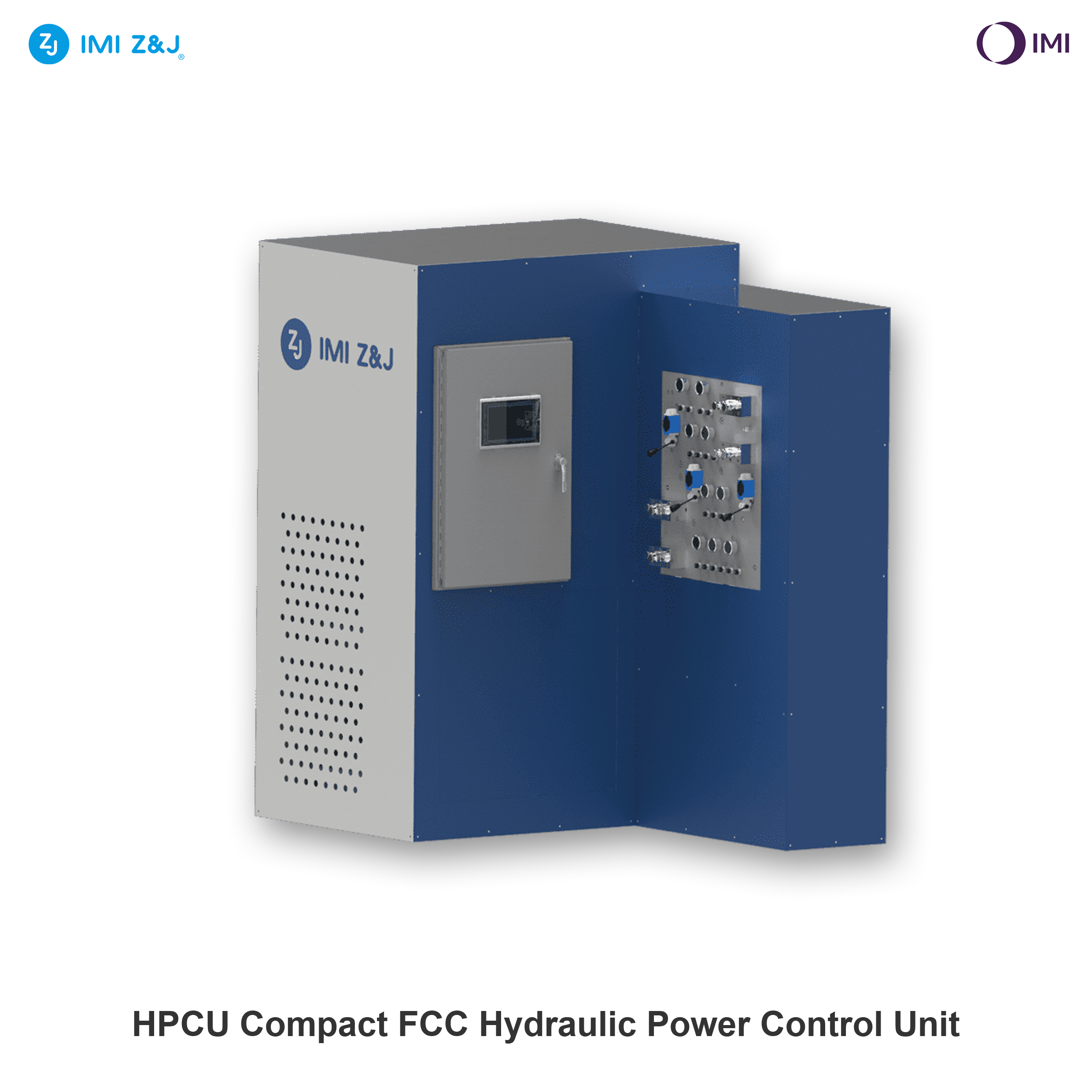

IMI Compact FCC HPCU

IMI Z&J’s HPCU Compact delivers high-performance valve control in a space-saving package. Designed with decades of industry experience, it combines easy installation, intelligent features, and low life cycle costs for FCC applications.

Key Features:

- Compact footprint for space-limited areas

- Low life cycle cost with high reliability

- Quick change manifold for easy maintenance

- Digital control system

- Standardized, fully stocked components

Pressure Gauge

Pressure gauges are instruments used to measure and display gauge, absolute, or differential pressure. Depending on the application, they use Bourdon tubes, diaphragms, or capsule elements to convert pressure into readable values.

Key Features:

- Measurement Types: Gauge, absolute, and differential pressure (positive & negative)

- Working Principles: Bourdon tubes for most applications; diaphragms for demanding conditions

- Materials: Plastic with copper alloy for neutral media, chrome with glycerine for vibration, stainless steel or coated for aggressive environments

- Accuracy Classes: Ranges from 4% (plastic) to 0.1% (test gauges), depending on material and use

Pressure Sensor

Pressure sensors convert physical pressure into electrical signals, while transmitters include standardised connections and output signals for easy integration. WIKA offers various sensor types for absolute, gauge, and differential pressure measurement.

Key Features:

- Sensor Types: Thin-film, thick-film, and piezoresistive sensors

- Function: Pressure is directed to a sensing element, converted into a scalable electrical signal

- Piezoresistive Sensors: Use silicon diaphragms; resistance changes under pressure for accurate measurement

- Differential Pressure: Measures pressure differences—ideal for filters, pumps, compressors, and pharma applications

- Transmitters: Include standard output and interface for simplified system use

Process Transmitters

WIKA process transmitters offer adjustable measurement ranges, zero points, and parameters—ideal for complex industrial and process engineering tasks. They support turndown functionality and integrate with diaphragm seals for high precision and flexibility.

Key Features:

- Scalable measuring range (turndown/scale-down)

- Rotatable display; available in plastic, aluminum, or stainless steel cases

- Suitable for pumps, vessels, pipelines, pharma, food, and outdoor use

- Models: UPT (universal), IPT/CPT (industrial), DPT (differential)

- Differential models support level and flow measurement in closed systems

Multipoint Thermocouple

WIKA is a global leader in multipoint temperature measurement solutions for refining and petrochemical industries. Trusted by major companies, WIKA offers both traditional and advanced sensor technologies to meet diverse application needs.

Key Features:

- Flexible technologies: FLEX-R® and FLEX-O® systems

- Traditional designs: pipewells, T-bar, spring-loaded, bimetallic, heat transfer blocks

- Mini-multipoint options for high point density and compact spaces

- Stuffed and drawn assemblies for demanding applications